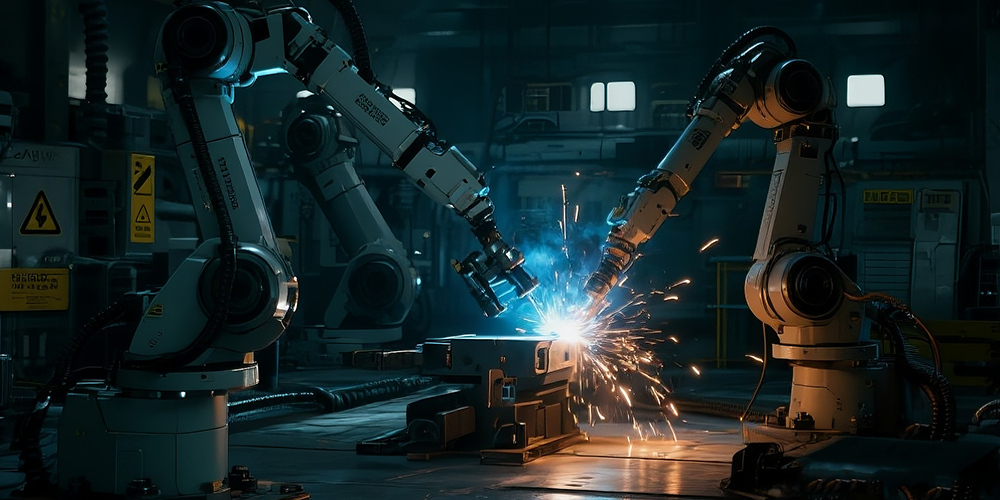

A welding chiller is a specialized cooling system designed to regulate the temperature of welding equipment and processes. By dissipating the substantial heat generated during welding, these chillers ensure that equipment operates within optimal temperature ranges, thereby enhancing performance and extending the lifespan of welding components. Unlike simple water recirculators, welding chillers actively cool by utilizing refrigerants to maintain consistent temperatures in industrial processes.

It will generate a lot of heat during the welding process, aIt will generate a lot of heat during the welding process, and effective cooling is crucial for the following reasons:

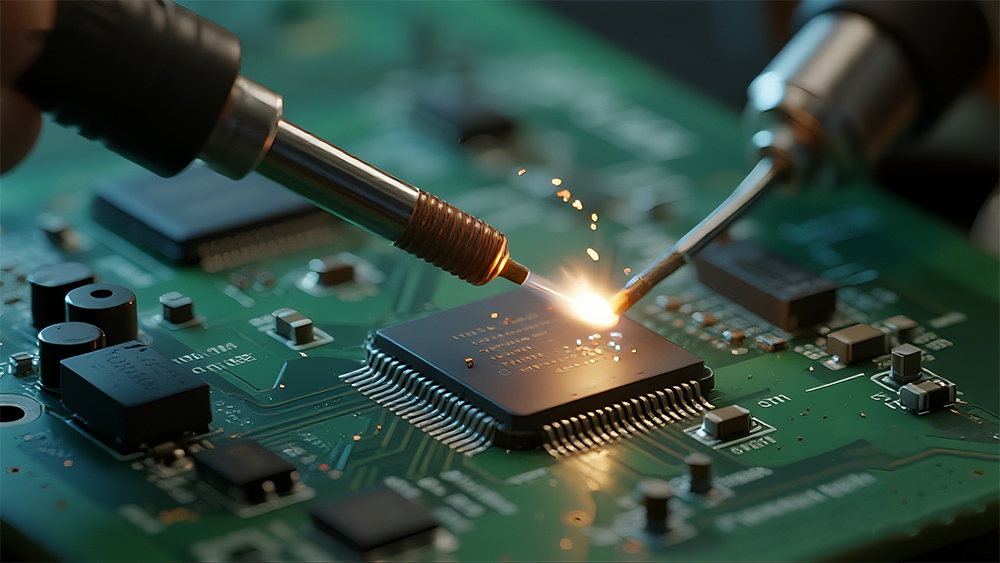

Consistent Weld Quality: Maintaining appropriate temperatures prevents defects such as cracks, holes, and inconsistent welds, ensuring uniform and reliable welds.

Extended Equipment Lifespan: Proper cooling prevents the overheating of components like welding tips and electrodes, reducing wear and tear and prolonging their service life.

Increased Uptime: The cooling system prevents critical components from overheating, maximizing equipment uptime and minimizing downtime.

Welding chillers function by circulating a cooling fluid, typically water or a water-glycol mixture, through the welding equipment. This process involves several key components:

Compressor: Pressurizes the refrigerant, increasing its temperature.

Condenser: Dissipates heat from the refrigerant to the surroundings, causing it to condense into a liquid.

Expansion Valve: Reduces the pressure of the liquid refrigerant, cooling it further.

Evaporator: Facilitates heat exchange between the cooled refrigerant and the circulating cooling fluid, which then absorbs heat from the welding equipment.

This closed-loop system ensures continuous removal of excess heat, maintaining optimal operating temperatures regardless of ambient conditions.

Assess the heat load generated by your equipment to determine the necessary cooling capacity.

Look for chillers that offer precise temperature regulation to maintain consistent operating conditions.

Ensure that the chiller is compatible with your existing waterjet system in terms of flow rate, pressure, and connectivity.

Opt for chillers designed for energy efficiency to reduce operational costs and environmental impact.

Choose products from reputable chiller manufacturers known for durable products and excellent customer support.