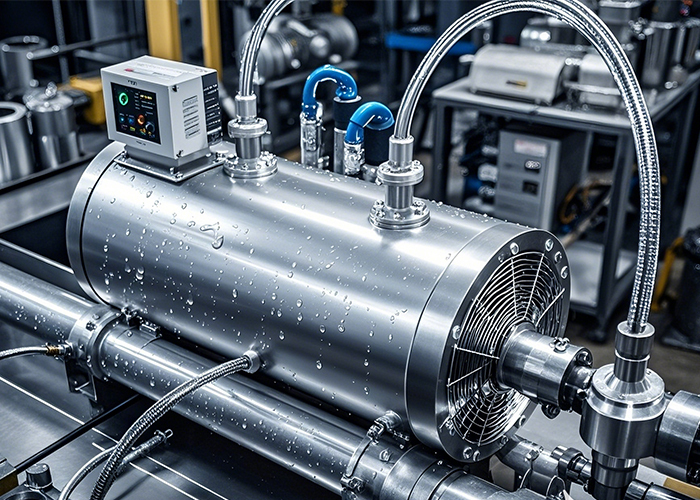

Waterjet cutting chillers are specialized cooling systems designed to regulate the temperature of waterjet cutting machines. By maintaining water temperatures below 65°F (18°C), these chillers prevent overheating, thereby protecting critical components such as pump seals and intensifier pumps from premature wear and potential failure. Consistent cooling ensures that the equipment operates efficiently, reducing downtime and maintenance costs.

During the waterjet cutting process, high-pressure pumps generate significant heat. If not adequately managed, this heat can lead to elevated water temperatures, adversely affecting the performance and durability of the machine. Effective cooling systems, like waterjet cutting chillers, are vital for dissipating this heat, ensuring that the machinery functions within safe temperature ranges.

Waterjet cutting chillers operate by circulating chilled water through the machine's components, absorbing excess heat, and then expelling it away from the equipment. This process maintains a stable operating temperature, which is critical for achieving precise cuts and prolonging the service life of the machine. Some chillers utilize a closed-loop system, which recirculates the cooling water, enhancing efficiency and conserving water resources.

Assess the heat load generated by your equipment to determine the necessary cooling capacity.

Look for chillers that offer precise temperature regulation to maintain consistent operating conditions.

Ensure that the chiller is compatible with your existing waterjet system in terms of flow rate, pressure, and connectivity.

Opt for chillers designed for energy efficiency to reduce operational costs and environmental impact.

Choose products from reputable chiller manufacturers known for durable products and excellent customer support.